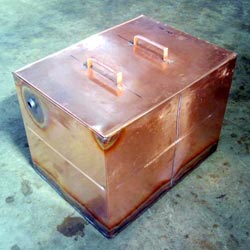

Header tanks suitable for use where temperatures could get high

What is the difference between a header tank and an F&E tank?

In a fully open vented heating and hot water system you will often find water storage tanks in the loft. It is quite common to find two. The function of each is however quite different.

You may well find that one tank (usually the larger of the two) is a Header Tank, whereas the other (the smaller) is a Feed and Expansion Tank (also known as an F&E tank).

Header tank

A Header Tank is a cold water storage vessel usually filled via a ball cock (or float valve) directly from the incoming cold water main. This tank stores the water that feeds to your hot water cylinder. The high position of the Header Tank creates 'a head' of water which determines the pressure of the hot water system in the property. System pressure can be calculated roughly by applying the following equation: Measure the vertical difference from the Header Tank to the point of outlet. A 10 metre differential will give 1 bar of pressure at the outlet, other height differentials can be calculated pro rata. Pressure can be raised by increasing the height the Header Tank in relation to the outlet.

F&E tank

A Feed & Expansion tank is typically connected to the 'heating' side (boiler or radiator circuit) of an open vented system allowing it to breathe. As its name suggests it provides a method of replacing (feeding) water that might evaporate as the system gets hot whilst accommodating expansion of the water contained within the system.

What should an F&E or Header Tank be made from?

Header tanks are commonly made from plastic, but can be made from a range of materials. Metal header tanks are better suited for use in systems where the water can become very hot due to the uncontrollable nature of the heat source. Such systems might include solid fuel installations, wood burning stoves, AGA, back boilers etc.

Use of a plastic tank in a scenario where water contained within could reach a high temperature is dangerous as the tank could sag or deform. In such an event boiling hot water could escape and pour through the ceiling below with devastating consequences. Using a metal Header or F&E tank safeguards against this awful scenario.