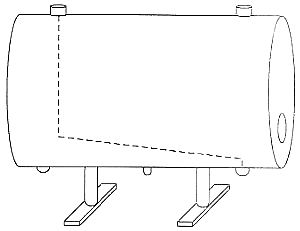

Direct and Indirect horizontal vented hot water cylinders

Can be

built to your specification. Supplied as direct or indirect patterns

and complete with cradles.

|

Above: Typical horizontal hot water cylinder with support cradles

(Colour and type of insulation may change)

|

So what's the difference?

Horizontal cylinders differ greatly

from their vertical counterparts. For example, a vertical cylinder

has a convex top and a concave base. When a cylinder is manufactured to lay on it's side

so to speak it is manufactured with two convex ends.

Connections on a horizontal hot

water cylinder.

Everything about a horizontal hot

water cylinder differs to the vertical counterpart. Vertical cylinders

tend to have the cold water feed on the side at the bottom with the

hot water draw off in the middle of the dome at the very top.

Because the domes on a horizontal cylinder are not at the top the

location

of these tappings also needs to be repositioned accordingly. |

The cold inlet on a horizontal cylinder

is normally positioned on the bottom of the vessel at one end.

The hot water draw-off is usually on

the top of the vessel at the opposite end to the cold water inlet.

A horizontal cylinder requires support.

The cylinder cannot just lay on it's side on the floor, it requires support. For this

reason, horizontal cylinders can be supplied with a steel cradle. The

cradle also stops the cylinder from moving - a full cylinder

becomes very heavy! You are of course at liberty to devise or make your own

support. Factory cradles hold the cylinder approximately 100mm above

the surface upon which it is supported, so remember to factor this into any

measurements. (i.e. Cylinder diameter + insulation thickness + 100mm cradle

height)

A slight slope

A horizontal cylinder should be installed with

a slight slope up towards the hot water draw off point. This encourages air

bubbles to work their way toward the vent, preventing the build-up of

an air pocket along the upper edge.

|

Boiler connections on an indirect

horizontal hot water cylinder |

|

Connections and internals on a horizontal

cylinder are very different to those found on a standard vertical hot water

cylinder. To illustrate this point, consider laying a vertical indirect

cylinder on it's side. The boiler water that was previously travelled in a

descending coil would now be effectively travelling in a rising and falling

motion - and near to one end only. This would cause many problems and would not work

efficiently. So in a horizontal cylinder the heater exchanger (boiler coil)

is modified to travel along the lowest part of the cylinder (in the coolest

water) from one end to the other. The boiler 'flow' is fed in through

the top of the cylinder, down to the heat exchanger at one end and returns

to the boiler through the bottom of the cylinder at the other end. |

|

The cold water feed to

the cylinder is typically on the underside of the cylinder below the point

where the boiler flow connects and the hot water draw-off in on top of the

cylinder above the boil return (as is the vent connection and shower

take-off if required).

The afore mention connection points can vary

according to cylinder function and manufacturer. For example, some

horizontal cylinders have connections in the domed ends.

A tapping for a drain is often

considered a good idea and can be incorporated on the lower side (bottom) of

the cylinder body.

Horizontal hot water cylinders with immersion heaters

Horizontal hot water cylinders can be fitted

with immersion heaters just like a vertical cylinder might. However, to keep

the element/s as low in the cylinder as possible it is preferable to have

immersion heaters fitted in the end/s of the cylinder.

Horizontal hot water cylinder and shower take-offs

A shower take-off can be

fitted to a horizontal hot water cylinder. The purpose of a dedicated shower

take-off is to draw hot water from a

level just below the top of the cylinder. In doing so air bubbles (which

naturally rise to the top) are prevented in the main from entering this

dedicated feed to a shower booster pump and negate problems one might

experience without such a fitting such as cavitation. (Ordinarily you would

need to purchase a device known as a 'Surrey Flange' to do such a job at extra cost.)

Horizontal cylinder fed by an 'unpumped'

heat source.

It is possible to heat a horizontal cylinder with an

unpumped heat source such as a wood burning stove or an AGA. Unlike the heat

in a typical household system in which hot water from a normal gas

or oil boiler is moved by a small circulating pump, unpumped heat sources

(as their name suggests) do not utilise a pump in to circulate water

through the heat exchanger, instead they rely on what's known as

thermosiphoning - a gravity

flow created by the action of warm water rising in external pipe work and cooler water falling.

To explain further, water heated by the appliance (AGA, Rayburn, woodburner, etc) is hotter than water returning

from the cylinder, so when pipe work is configured correctly hot water will rise

to the cylinder, give up its energy, then return to the heating appliance as

cooler water

for the cycle to repeat itself - a circulating flow being created. This is

an 'age old' and very simple principle which is quite effective. You will

however need a larger bore heat exchanger in the cylinder than the

type used in a fully pumped system to ensure a good flow of water for this gravity principle to work well. Do not use a cylinder

designed for a pumped heat source on a system relying on gravity

circulation.

Horizontal hot water cylinder with gravity boiler coil.

Horizontal cylinders

can be made with a gravity coil (for an unpumped heat source), but you must

specify this requirement. Failure to do so will result in you receiving a

standard cylinder suitable for use on a pumped system. A gravity boiler coil

is a little more expensive than a pumped coil for the simple reason it is

larger. Please refer to price tables.

Options for fittings. We can supply

your cylinder with various types of connections depending on your

requirement and preference. We can also configure your cylinder with the

tappings (connections) in positions that best suit your installation. If you

have special requirement you are welcome to call

and discuss your installation before

making purchase to ensure we arrive at the best possible solution.

UNVENTED HORIZONTAL HOT

WATER CYLINDER

Frequently Asked Question

Q. Can you supply a horizontal unvented

cylinder to provide mains pressure hot water?

A. Yes. We are able to supply mains pressure

horizontal hot water cylinders manufactured from either Stainless Steel, but

not on this page. Please call for advice.

All the cylinders offered on this

page are 'vented type'. Under no circumstances must the inlet be connected

directly to mains pressure water. |