|

Hot water cylinder terminology |

|

| |

| You may find the terminology used to

describe a hot water cylinder a little confusing.

Direct....

Indirect.... Combination..... Solar.... What does this mean? Click on

your question below -

|

| |

|

|

Know enough? |

|

If you feel

comfortable with the terminology and wish to make a product

selection click on the button below to go to the cylinder

page.... |

| |

|

|

|

|

| 1. |

Categories of Hot Water

Cylinder |

| 2. |

|

| 3. |

|

| 4. |

|

| 5. |

|

| 6. |

|

| 7. |

|

| 8. |

|

| 9. |

|

....It all depends where the

cylinder gets it's heat from.

Please note:

Information contained on this page is intended to assist with your

understanding of cylinders and terminology. It does not represent a definitive

description of each and every product available. If in any doubt, please call

for assistance - we will be pleased to help.

|

|

Categories of hot water cylinder |

There are several

categories of cylinder that can be split into types. To simplify matters we

will firstly deal with Category.

- Vented

- Unvented

- Thermal store

The category depends on how you intend to

supply cold water to the cylinder which in turn will determine what you can

expect in the way of performance from the cylinder.

There are essentially two methods of

supplying water to a cylinder...

- Directly from the incoming cold water

main - known as a mains pressure supply

- From a holding tank (also known as a

Cistern, Header Tank or Storage tank) - known as a gravity supply

It is most important that you never connect

a cylinder designed for a gravity supply to a mains pressure supply. To do

so is highly dangerous and the risk of explosion exists.

The only type of cylinders you may connect

directly to a mains pressure supply are the Unvented Type and Thermal

Stores. Both of these are designed to handle the higher pressures associated

with a mains supply and will deliver mains pressure hot water - albeit is

slightly different ways.

Unvented cylinders: These are

essentially pressure vessels. You fill them with water at constant mains

pressure, heat the contents (by whatever means) and when you open a tap the

incoming pressure forces the contents (hot water) out - hence mains pressure

hot water.

Thermal Stores: Deliver mains

pressure hot water but achieve the same result in a different way. A thermal

store could be likened to a large bucket. The water in the bucket is heated

by whatever means. By immersing a heat exchanger in the bucket and passing

mains pressure water through it the heat from the water in the bucket is

transferred to the water passing through the heat exchanger, which emerges

as it leaves the thermal store as mains pressure hot water.

The advantage of a Thermal Store over an

Unvented Cylinder is the Thermal Store can remain open vented - that is to

say there is no pressure in the stored water, only in the heat exchanger

(unlike the Unvented Cylinder that has a huge amount of very hot water under

constant pressure). This makes Thermal Stores inherently much safer. Whilst

rare, Unvented Cylinders have been known to go 'over temperature/over

pressure' which has lead to explosion. For reasons of safety the

installation of Unvented Cylinders is governed by Section G3 of the Building

Regulations.

Vented Cylinders (also known as

Gravity Cylinders): Get their name from the source of the water that

supplies them. When water is supplied from a header tank it relies on

gravity to get where it needs to go. The height of the header tank above the

final outlet point determines the pressure of the water at that point. A 10m

head of water will produce 1 bar albeit very rare to be able to achieve such

gravity pressure in most domestic houses. Gravity cylinders are designed to

handle lower pressures than mains water is normally supplied at. Gravity

cylinders are Graded for the head of water they can handle -

Grades of Cylinder

Cylinder Configurations: (Please

refer to the rest of this section for more detailed explanations of types)

Unvented: High performance pressure vessel. Can be Direct or

Indirect. Heat sources must be controllable. Solar Compatible. More

information and product guide here

Thermal Stores: Mains pressure hot water from open vented store.

Requires F&E tank*. Can be configured to handle multiple heat sources

(Direct & Indirect, Solar) simultaneously. Particularly suitable for

uncontrollable heat sources such as AGA, Rayburn, Wood Burner etc. Available

as 'cylinder' or combination' types.

More info and

product details

Vented: Must be fed from header tank. Low pressure output which can

be pumped if necessary. Suitable for all types of heat input.

Guide to available products

*F&E tank = Feed and expansion tank required

the enable cylinder to breathe. |

| |

|

|

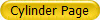

DIRECT HOT WATER CYLINDER |

|

The meaning of 'Direct Cylinder' has change somewhat over the years. In the

early days (when fires used to have copper back boilers) a direct cylinder

might simply have had flow and return from the back boiler feeding directly

to/from the cylinder (no heat exchange within cylinder). Your domestic hot water would

have been heated in the back boiler then passed back to the cylinder -

eventually providing a cylinder full of hot water heated 'directly' by the

back boiler. Such systems were typically unpumped - relying on gravity

circulation (also known as 'Thermosiphoning' where hot water rises, cooler water falls

creating circulation within the system).

Although the traditional back boiler became rare through the inconvenience

of having to light a fire every time hot water was required the concept has

enjoyed somewhat of a revival more recently with appliances like wood

burning stoves, although the more traditional appliances such as AGA and

Rayburn have always persevered with the concept. However, the modern back

boiler heat exchanger tends to be made from cast iron rather than copper.

For this reason it is necessary to separate the primary (heat source) water

from the domestic water (what you see coming from your taps) by a heat

exchanger within the cylinder - thus preventing contamination.

Cylinders that work with the

principle of thermosiphoning are slightly different to those designed for a

fully pumped system.

More information is contained in this

section. |

|

The term 'direct' continues within the industry, it's just the meaning that

has changed.

A

modern Direct Cylinder is typically heated by electrical immersion heater/s

located within the cylinder. Because

the Immersion Heater is heating the water 'directly' within the cylinder it

too is known as a

'Direct Cylinder'. In a direct cylinder there are no other external heat

sources.

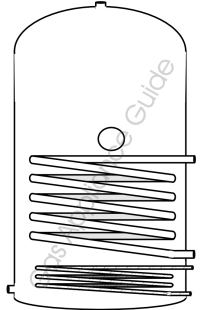

The diagram

shows a 'direct' cylinder with two side mounted immersion heaters.

Please note: Variants may

include:

-

a side mounted single

immersion heater boss

-

a top mounted single

immersion heater boss

-

one side mounted and one top

mounted heater boss

-

two side mounted heater

bosses

-

more than two heater bosses

You should specify the

number of heater bosses you require and their desired position. The diagram

is only intended for the purpose of explanation.

Immersion heater elements are not normally fitted

or included in the price of a cylinder and should be specified if required. |

|

Back to top of page |

|

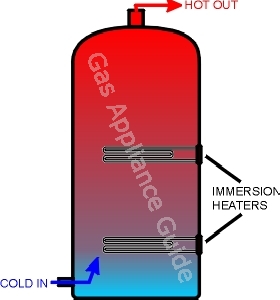

INDIRECT HOT WATER CYLINDER |

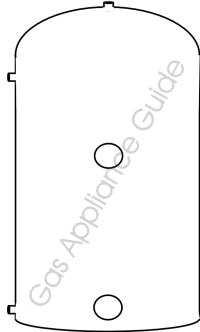

| A cylinder is deemed 'indirect'

whenever a heat exchanger is fitted within. This is to say, whenever a heat

source is external to the cylinder and utilises a heat exchanger to impart

heat to the contents of the cylinder the cylinder is deemed to be

'indirect'. A cylinder could be both

'direct' and 'indirect' in certain scenarios. |

| Although heat may be imparted to the cylinder by a heat exchanger

located internally, the heat source is actually remote - such as a gas

boiler, solar panel, heat pump, wood burning stove, Aga etc etc. It is therefore deemed

that such a cylinder is 'Indirect'. Indirect

cylinders may be fitted with immersion heaters as a supplementary 'direct' heat source

but the cylinder is still deemed to be 'Indirect'.

An indirect cylinder may have more than one

heat exchanger (also referred to a a coil) depending on the number of remote

heat sources feeding the cylinder. (i.e. 1 x boiler coil and 1 x solar

coil = twin coil indirect cylinder, or, 1 x boiler, 1 x AGA and 1 x

solar = triple coil indirect.)

The term 'indirect' may apply to a vented cylinder, an unvented cylinder or

a thermal store. It simply refers to an external heat source heating the

cylinder via a heat exchanger.

An Immersion heater boss may be

fitted through the top of the cylinder. You should specify your requirement.

Immersion heater elements are not normally

fitted or included in the price of a cylinder and should be specified if

required. |

|

|

|

Back to top of page |

|

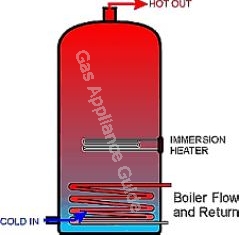

COMBINATION HOT WATER CYLINDERS |

| A gravity-fed household copper cylinder is

typically supplied from a tank sited above the cylinder - often

located in the loft. This height of this water store (also referred to as a

'cistern' or 'header tank') is what creates the pressure in a gravity water

system. The higher the header tank the greater the 'head' of

water and hence the higher the gravity pressure when measured at the outlet

point. (Also refer to Section on

Grades of Cylinder).

Pressure in a gravity system varies throughout

as the height differential between the header tank and the outlet point

varies. Example: A 10m head of water will create 1 bar of pressure at the

outlet. Using this simple formula you can calculate the approximate pressure

at any outlet by measuring the distance from the outlet point to the header

tank above. You might begin to appreciate why gravity systems are often

referred to a 'low pressure' systems as it is most unlikely that 10m is

anywhere near achievable in most domestic properties. |

|

Where the property is unable to accommodate a header tank (for example in an

apartment or flat) the header can be accommodated literally on top of the

cylinder and built into the unit. The cylinder therefore combines the

'header' and the 'storage' elements and becomes a COMBINATION cylinder. Note: The output water pressure from a

combination cylinder is often poor due to the small distance (head) between the

header section and the outlet point (i.e. A tap). This can be exacerbated when

supplying hot water to a shower outlet when the height of the cylinder

header section and a wall mounted shower handset can be virtually the same -

resulting in zero head and therefore no pressure.

Combination Cylinders may be Direct, Indirect or Economy

7. They simply combine the header function.

Thermal stores may also be configured to be

'combination type' but for a very different reason. Please refer to

'Thermal Store section' for further info.

Immersion heater elements are not normally fitted

or included in the price of a cylinder and should be specified if required. |

|

Back to top of page |

| SOLAR

HOT WATER CYLINDERS |

| A 'solar cylinder' is a hot

water cylinder that has been configured

to accept 'wet' solar energy. To

explain, there are essentially two types of energy we try to harvest

domestically from the sun - radiant energy (the warmth from the sun) and

photovoltaic (using the light - also referred to a 'pv'). The latter is

where sunlight is converted to electricity. The resulting electrical energy

can be utilised in numerous ways and is therefore not exclusive to the

production of hot water. The former (the radiant energy) is typically

captured by 'wet' solar panels - so named because they contain and utilise a

fluid (rather like antifreeze) to capture and transport the gathered energy.

Although pv energy can of course be use to

heat a cylinder of water with electrical immersion heaters, no special

modifications need to be made to a standard cylinder to accommodate an

electrical immersion heater - a fairly standard feature. To store solar

energy on a 'wet' system is however somewhat more complex and requires a

cylinder to be equipped with a 'solar coil' in order that energy may be

imparted to the cylinder contents. |

| A solar coil is usually located at the very

bottom of a cylinder. Although 'free', solar energy is not as vigorous an

input as say that of a gas boiler so is generally regarded as a low grade

heat source. By placing the heat exchanger at the bottom, energy when

available is percolated throughout the entire cylinder through a high

efficiency coil with a large surface area that facilitates maximum heat

transfer. For the discerning, the

presence of a solar coil in a cylinder facilitates the future addition of a

wet solar system even if the necessary hardware is not immediately

available. Known as 'future-proofing' this is becoming popular (and arguably

logical) as it saves major disruption and further expense by having to

change the water storage cylinder when solar collectors are eventually

introduced to the system.

Solar coils can be fitted in most types of

cylinder (vented, unvented and thermal store) at the time of manufacture. It

is not however a feature that can be retrofitted or bought as an accessory.

Also see:

|

|

Back to top of page |

| ECONOMY 7

hot water Cylinders |

| An Economy 7 cylinder is

designed to exploit 'off-peak' electricity - typically available throughout

the night. Because you are heating

your cylinder overnight it is important to not to loose the stored heat.

Economy 7 cylinders are therefore fitted with an extra thick jacket of

insulation to minimise standing heat loss.

Economy 7 (or indeed Economy 10 where

available) cylinders usually have two heating elements. The lower element

energises as the economy tariff becomes available (via an off-peak switching

device). This heater heats the whole cylinder over several hours - taking

longer because it heats the entire volume. The upper heater is normally used

as a 'boost' element providing a quicker response because it only heats

water at the top of the cylinder and is manually energised when required.

Economy 7 cylinders are available as direct

and

indirect

models of 'cylinder' type or 'combination' type.

|

|

Back to

top of page |

| |

|

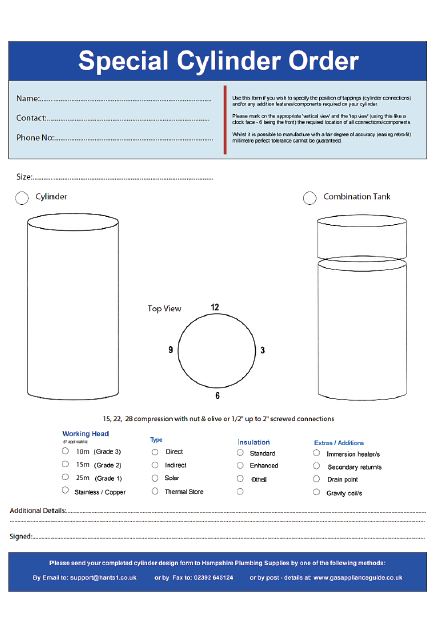

Configuring or Specifying a hot water cylinder to your own design |

| Never buy a hot water cylinder

believing it to be a 'standard' configuration. Different manufacturers and

indeed different areas of the UK have their own interpretation of what

'standard' means. For example,

cylinders made in Yorkshire by one manufacturer might fit 1" bosses as

connections with boiler connections to the right and cold feed to the left,

whereas another made in Hampshire might use compression fittings and have

connections the opposite way round! Try replacing one for the other and you

may have your work cut out! |

| It doesn't pay to be complacent. This is

especially important if you are replacing an existing cylinder. The one you

take out might have been made to special order thereby facilitating pipe

connections in an awkward installation. Or worse still, the last plumber

didn't think the original job through well enough which meant a difficult

install and even more difficult replacement.

Part of the service we offer is to supply a

cylinder with connections (tappings) configured to your requirement. This is

a fairly simple process and make life so much easier when it comes to

retrofit.

Simply use our

online form to sketch

your requirement and post, fax or email it to us.

Help is always at hand. Simply

call us for assistance if the going gets

confusing or you wish to discuss matters in detail. |

|

Back to top of page |

| Grades of

gravity hot water cylinder |

| Gravity hot water cylinders are available in three

grades. The grades refer to the pressure of water they can withstand from the

header tank (the pressure created by the height of the header tank above the

cylinder).

In simple terms, this translates to

the gauge (thickness) of copper used in construction. Do not confuse a

gravity

cylinder with mains pressure or unvented cylinders. Connection of mains

pressure water to any cylinder designed for a gravity feed can be extremely

dangerous. |

Grade 1 - Can withstand a

25 metre head of water |

| Grade 2 - Can withstand a 15 metre

head of water |

| Grade 3 - Can withstand a 10 metre

head of water It is possible to supply a gravity

cylinder that will withstand a 31 metre head. This is achieved by doming the

bottom of the cylinder. These cylinders sit in a ring mount. Please specify

the working head of the system into which the cylinder will be installed.

A normal domestic cylinder is

usually a Grade 3. (All prices quoted on this website refer to Grade 3

cylinders unless otherwise stated) |